A garage/shop where there is potential for prolonged exposure to oils, brake, and transmission fluids. Outside and wet areas where water can sit on the floor for long periods of time. Commercial kitchens.

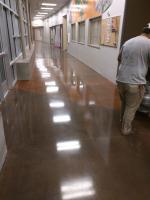

Concrete Honing and Polishing

This is the most cost effective option when you consider the minimal maintenance costs involved compared to nearly ANY flooring type. This is now the go-to option for high end lofts and homes, retail stores, big box stores, warehouses, & restaurants. Several dozen color choices and affordable lower shine options are available.

What is it and how do we do it:

We first grind off your concrete surface to open up the pores for our densifier application. This strengthens your concrete by means of a chemical reaction that creates a densely bonded crystal structure in the top surface layer. Next, we hone the surface smooth to give you an easy to clean glossy surface. Process is completed by heat bonding and curing an industrial protective coating into the polish for maximal chemical and abrasion resistance.

See the FAQ on polishing below to learn of it's pros and cons.

Gallery

Frequently Asked Questions

- Where should you NOT install a polished concrete floor?

- Are concrete polishes and stains environmentally friendly?

Absolutely! With polishing, the chemicals used to strengthen your existing concrete are extremely safe. There is no waste or material that eventually goes bad and needs to be thrown out and replaced, you're just using your existing floor to it's full potential! We also do not use acid based stains and so there is no harmful waste involved in our concrete staining/dying process.

You may also qualify for LEED points on your project by choosing a polished concrete floor.

- Can your concrete flooring options save me lighting or cooling expenses?

Yes, when you choose a highly polished concrete floor or a bright colored epoxy, the lighting in your room goes a lot further, reflecting off the floor and helping to illuminate your space. In the summer you can also save on cooling costs.

- What are my options regarding colors?

Contact us for color charts and design suggestions. A molted one or two color design pattern is very popular. You can have company logos, names, symbols, football teams dyed onto your floor. We can make you a variety of patterns including checkered, diamond, wavy lines, symbols, or colored pathways. If you have a design in mind we can work with you to put that down on your floor.

- What is a polished concrete floor?

A polished concrete floor is a concrete floor that has been honed smooth and undergone a strengthening densification reaction. The densification process is a transformative chemical reaction which produces a dense crystalline lattice in the top layer of your concrete. This increases your floors resistance to the following: Abrasion, impact, chemicals, stains, chipping, pitting, erosion. It makes your concrete less porous while increasing it's density, sheer strength, and tensile strength. To top off this we apply a silane based clear coat that we melt into the floor for added chemical and stain resistance. This process creates a surface that can still transmit moisture vapor from inside your concrete floor (a good thing), while making the surface too dense to easily transfer liquid/chemical stains. The polar bond in most common chemical/ liquid stains remains intact, simply beading and pooling on the concrete surface, unable to penetrate the sealer or your concrete's dense crystal filled pores.

- What are some cons to polished concrete floors?

Not all floors are suitable for polishing, if your concrete slab has many large cracks or holes that you'd like patched, these patches will stick out. If your concrete floor is very uneven or wavy a polish may bring these imperfections out. The price can be relatively high for a very high gloss finish compared to stain & seals or one colored epoxies. Polished concrete floors can be susceptible to staining by certain chemicals, especially strong acids or bases and may not be suitable for laboratories or workplaces handling them. Negligence in cleaning up spilled stains, chemicals, or hard water, will likely leave a stain if left sitting on the polished floor too long. Polished concrete floors are also unsuitable for commercial kitchens exposed to high levels of grease which will create a slippery surface. Here an epoxy floor with aggregate is more appropriate. Give us a call and we can help you pick the most suitable floor options.

- What are my polished concrete floor options?

You can choose one or multiple colors as well as your level of shine:

Flat finish: 50 grit

Matte finish: 100 grit

low-gloss: 200 grit

Medium-Gloss: 400 grit

Glossy: 800 grit

High Gloss: 1500 grit

Maximum Shine: 3000 grit

- Where can I see some of your polished concrete work in person?

Westminster: Fruehauf Patio Furnature. 19,000 s.f. Extensive repairs were made, joints were filled, and floor taken to a medium-gloss polished finish. Address: 6795 W 88th Ave, Unit A, Westminster, CO 80031

Commerce City: Adams City High School: Job Details: 5,800 s.f. Concrete polish after water damage was taken to 1500 grit with a burnished clear coat. Address: 7200 Quebec Pkwy, Commerce City, CO

Colorado Springs: Rock Family Church: Job Details: 17,200 s.f. including carpet, glue removal, & hole patching. Polished to a low shine flat finish. Address: 4005 Lee Vance View, Colorado Springs, CO 80918

Centennial: The Clue Room. Job Details: 2,200 s.f. Job involved demolition of wood flooring, VCT, glue, patching holes, colored logo, 5 different colors applied, borders, polished to a medium-gloss finish. Address: 7255 S Havana St Ste 101, Centennial, CO 80112

Aurora: Golden Flame Hot Wings. Job Details: 1,100 s.f. Job finished over two day holiday involved removing a thick epoxy coating less than a year old, hole patching, coloring with 'concrete gray' dye, and polishing to a medium-gloss finish. Address: 18757 E Hampden Ave Ste 156, Aurora, CO 80013

Lone Tree: Functional Strength Pilates: 1,400 s.f. Low shine polish with Welsh Slate Color added. Address: 10047 Park Meadows Dr., Lone Tree, CO, 80124

Highlands Ranch: Indian Market. Job Details: 3122 s.f. included glue removal, conduit clean out removal, patching holes from old walls and conduits, and bringing the floor to a 400 grit polish followed by the burnish of a clear coat layer. Address: 7152 East County Line Road Highlands Ranch CO

Parker: Golden Flame Hot Wings. This 1,400 s.f project combined two adjacent retail outlets into one with a medium-gloss polish having elastic polyurea filled joints and a black dye. Address: 16524 Keystone Blvd, Parker, CO

- What do I do with my baseboards?

You can leave these on if absolutely necessary but realistically, you should remove these for any kind of flooring work your considering; concrete or otherwise. We can do this for you if you like.

The details: While we have done plenty of work without removing them, it's not advised, and it will cost you more for us to have to carefully work on your concrete floor without doing too much damage to them. If you insist on leaving your floor boards on while we work, it should be still noted that they will inevitably get nicked, scratched, damaged, and dinged in places. Our tools have to be very powerful to grind concrete floors and your option is to either have unfinished edges or for us to try to get right up against them with 8,000 rpm hand grinders spinning a diamond embedded metal alloy disk. If you're getting an epoxy done, your baseboards will be partially embedded in the epoxy floor, this is especially the case for a reflective/metallic epoxy floor that has a thick build. With concrete floor polishing, the chances of damaging them goes up as we have to make numerous passes along your edges with ever finer polishing grits.

- Do you offer a warranty and what does it cover?

Yes, a one year warranty comes standard on all of our workmanship. If you'd like an extended warranty we would be gland to oblige you. We don't take shortcuts in our prep work or materials and so are glad to offer you written reassurances on our products and services.

- What are my options for the control joints with a Polished Concrete Floor or Stain & Seal?

-

Leave them as is. A very common option, but dirt & debris get stuck in there making cleaning difficult.

-

Fill them with a elastomeric polyurea compound that will stretch and contract as your concrete moves. This will also help protect your concrete at the joint lines. It eliminates a blunt impact by wheels and dragging objects. It also makes your floors far easier to clean. Not to mention safe for high heels, roller blades, pogo sticks, and the like not getting stuck and preventing a potential tripping hazard.

-

- What is the process for installing a polished concrete floor?

We start our the process by exposing your concrete floor's inner surface layer using high end concrete grinders equipt with diamond embeded bits. We use HEPA filtered dust extractors to maintain a clean environment while we work. The next step is to apply a top end (Colloquial or Lithium based) densifier to your concrete to initiate the hardening and strengthening chemical reaction in your floor. Next, we carefully hone a shine into your floor by using ever finer diamonds to achieve your desired level of glossiness. It is this process that separates the experts from the amateurs in this industry, as it requires hitting your concrete floor from multiple angles at just the right speed with just the right tool, set at the proper power level and keeping a close eye on your floor to make sure that no spots are missed or neglected. Finally, we melt an industrial grade protective coating into your floor with a heavy duty high speed burnisher. This process enables the guard layer (a silane based polymer) to form a strong covalent bond with your polished concrete floor. This coating will act as a wear surface that will prolong your floors shine and strength.

- How do you recommend I maintain my polished concrete floor?

Because a polished concrete floor is so durable, it requires less maintenance than nearly any other flooring choice. Nonetheless, you should try to keep your floor free of dirt and debris that can slowly wear down the smooth surface. Periodically it's recommended to re-apply a protective coating we refer to as a guard. Re-application timing will depend on your usage. We can provide you with a maintenance schedule, but generally if you're a moderately busy retail store, once every six months should suffice. For residential usage, a year or more is typical. It can be easily applied with a micro-fiber mop. We also offer a maintenance plan which absolves you from worrying about when to re-apply and we use a more industrial burnish activated coating.

- Are polished concrete floors slippery?

Like any floor, it can be when wet and so it isn't recommended outside or in places subject to greases and oils. We wouldn't recommend it in a bathroom, kitchen, or garage. It gives good traction in most conditions and wouldn't be the flooring choice for most big box stores, many grocery chains, and many modern high end lofts and homes if it were a hazard of any kind. Lower gloss levels do give slightly higher coefficients of friction and so if this is a big concern for you and you'd like to be more on the safe side of things, go with a matte finish.

- Which gloss level should I choose for my polished floor?

The answer is really one of taste, but, we would tell you to consider the following factors in your decision making process. Those being the quality of your existing floor, your budget, and the traction requirements.

A floor with lots of repairs would be better suited to a higher gloss shine because the light reflections will serve to hide the various cracks, patches, and possible trench lines. The gloss overpowers many of these imperfections and blends them together much better. On a matte finish any repairs really stand out at you much more than on a high shine finish. We would typically never recommend going below a 400 grit gloss level in either case given the fact that lower than this you're not getting a true polish and persons who incised we do this weren't quite happy with the end result, even though they did save on the costs of not going with a higher gloss.

A highly polished floor would provide slightly less traction than one will a lower shine finish. We went with only a 400 grit polish at the Golden Flame Hot Wings store because of the possibility of grease tracking from the kitchen for example. - What is the cost of a polished concrete floor?

For the most part price is determined by how shiny you want your polished concrete floor to be. Other big determinants are how much repair work you want done on your concrete. Whether you want to fill in your control joints or not. If you're getting a color with your polish or not. If we can get our 1,000 lb. grinding machines into your space and whether you have adequate power supply or we have to use a generator. If you want us to work overnight on a rush schedule through weekends or holidays. Lesser factors include: How far away from our shop you're located.How much work you're having done. Some discounts are possible too: If you're paying by cash or check, are an existing customer, or served in the military. All these factors have to be calculated and more to give you a final price. We have a civil and mechanical engineer come out to your home or business, assess the condition of your floor, and provide you with a free estimate. We'll provide you with many prices and options within 24 hours of after seeing your concrete floor.

- Which of your flooring options are suitable for persons suffering allergies or asthma?

Polished Concrete, Concrete Stains, and Epoxies are all excellent choices. They do not support the growth of molds, pollens, or dust mites. If you have a kitchen or laboratory project in mind let us know, we have numerous products that are specifically FDA approved for these applications! We also have special coatings that are specifically suited to kill bacteria, molds, and fungi on contact.

- How long do I have to wait after a new slab is poured to finish it with epoxies, stains, or a polish?

28 days is recommended for all of the above. If you're getting a new slab poured and are thinking of using our services to finish your concrete floor, please give us a call first, we can provide you with some suggestions regarding the concrete mix and curing additives; especially if going with a polish! Some non-retarding concrete curing additives can increase the cost of your polish.

- What are my concrete floor options?

You can do a stain and clear coat, an epoxy and clear coat, two coats of polyaspartic resin, a urethane based cementitious coating, a microtopping, or a polish. Each has it's advantages and disadvantages as well as unique options that may or may not suite your needs and application, a brief phone call to us can help us guide you in the right direction.

- How do I clean my polished floor?

You should use a ph neutral cleaner such as 'Simple Green' with a micro-fiber mop to clean up chemical spills. You would follow that up with plain water and finally dry off your concrete floor. If your floor is just a bit dirty or dusty, you can simply use a dry micro-fiber mop.

- Do you offer maintenance plans for polished concrete floors?

Yes, we will assess your floor usage and contact you at the appropriate times to schedule a cleaning and protective coating application. We will at those times examine your floor and tailor our schedule to meet you and your floors requirements. We would use a more industrial coating that requires high pressure and high speed burnishing. This product literally melts into your polished concrete floor providing you with superior protection, longevity, and less frequent maintenance. We provide our customers with a maintenance schedule upon completion of your concrete floor polish. Give us a call and we can help guide you with your polished concrete floor maintenance program.

- Why coat or finish concrete in the first place?

Your concrete as a part of your total building infrastructure is often a very substantial part of the complete cost and by finishing it you can maintain that value so that it doesn't degrade. Aesthetically, when people see a concrete floor unfinished it gives the impression of a non-functional storage place and not a living, working, or professional environment. Bare concrete emits concrete dust when unsealed. It is susceptible to staining quite easily. It is liable to absorb oils and other contaminants deep into itself making it impossible in some cases to decontaminate. It is not resistant to molds, bacteria, or fungal growth and so can potentially be a source of pathogen contamination in certain circumstances. It is not easy to clean as it attracts dirt and holds it in its pores. Cleaning costs are far reduced on a coated surface. Concrete coatings help protect the surface from wear. Including salts, oils, water, chemicals, etc. Coatings typically reflect far more light than bare concrete and many other surfaces thus reducing electric bills. You may save costs long term dealing with repairs when not addressed properly sooner. In places with any sort of wheeled traffic control joints are often points of wear when they aren't filled in to allow wheels to smoothly transit the gap in the joints.